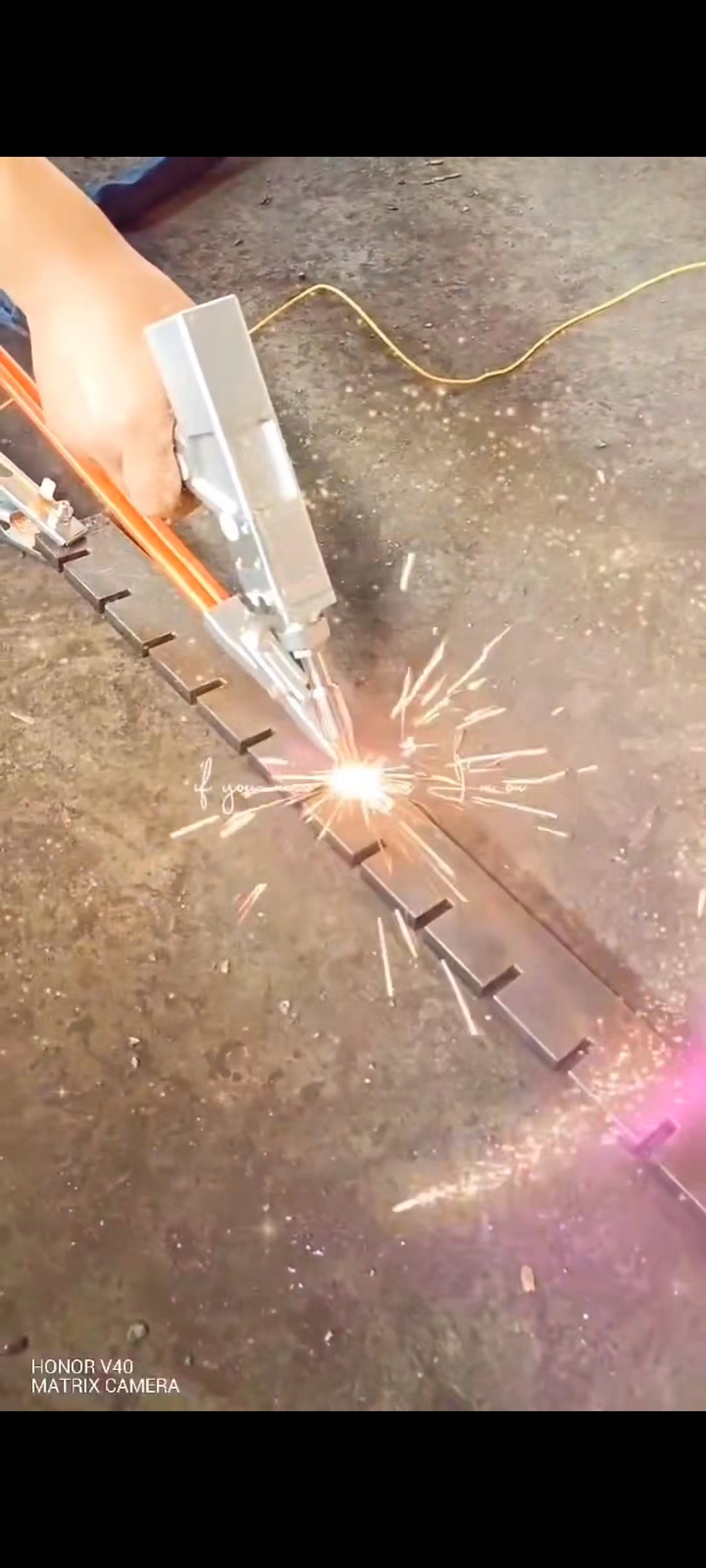

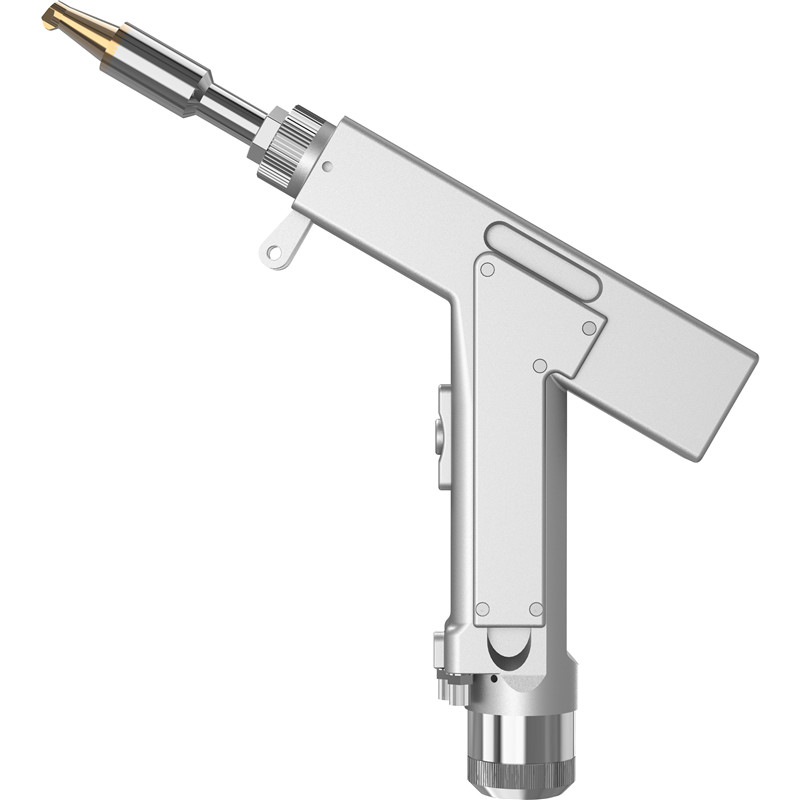

Welding torch principle and use method

Working principle:

The welding torch uses the heat generated by the high current and high voltage of the current to gather at the end of the welding torch, and the melted wire penetrates into the part to be welded. After cooling, the welded object is firmly connected into one.

The power of the torch depends on the power of the welder and the welding material.

Welding torch welding effect qualified, welding safety, fast speed.

The welding torch has reliable performance, simple maintenance and convenient adjustment.

Welding gun does not use electricity, save steel, equipment investment is small and other advantages.

Use of welding torch:

When we want to weld, we should first choose the appropriate model and different caliber welding nozzle according to the size, thickness and thermal conductivity of different welds. Operation, first unscrew the acetylene switch, and then slightly unscrew the oxygen switch, lit acetylene block, then the flame temperature is not high, the nozzle presents two layers of white flame core, in addition, due to acetylene excessive combustion is not complete, often black smoke, light a little before the other effect of oxygen is to reduce black smoke. To welding, adjust the oxygen switch, so that oxygen and acetylene gas appropriate, sufficient combustion, high temperature. When welding, the joint of the weldment is first burned to the degree of red heat, and then the welding rod is burned on the weld and filled to the joint. After melting together, the oxyacetylene flame can be withdrawn, and the welding is completed by cooling.

Selection of electrode:

Whether welding or repairing, it is necessary to choose the appropriate electrode as the filler metal. The strength and performance of the joint are not only related to the welding process, but also directly related to the material of the electrode we use.

Generally speaking, the melting point of the welding rod should not be higher than the melting point of the welding parts, otherwise it is not good to master the weld metal pool in the welding process, so that the welding molding deteriorates.